The sugar factory can be considered to be a mammoth industry. The different types of processes, equipments and components which are involved here are stated to be a bit complicated. On close observation, one can infer that most of the work performing in this industry is almost dependent upon the efficient and smooth functioning of the boilers. A key factor that is to be taken proper care of is evaporation for enhancing the firm’s overall productivity. During the process within the boiler, intense temperature and pressure are generated.

Consequences of neglecting tube cleaning in the sugar industry

The following consequences can be noticed that could result due to impure boiler tubes like:

- Development of sludges and scales occurring within the boiler.

- Firm’s productivity automatically goes down, while input requirements increases, thereby diminishing productivity and increasing costs.

- Heat transfer rate is retarded. It results in inefficient evaporation process.

- Prolonged exposure towards these types of conditions without appropriate cleaning may cease component working. Often, there could be a need to have them replaced.

It is equally important to have the boiler inspected on a periodical basis and to perform proper cleaning operations.

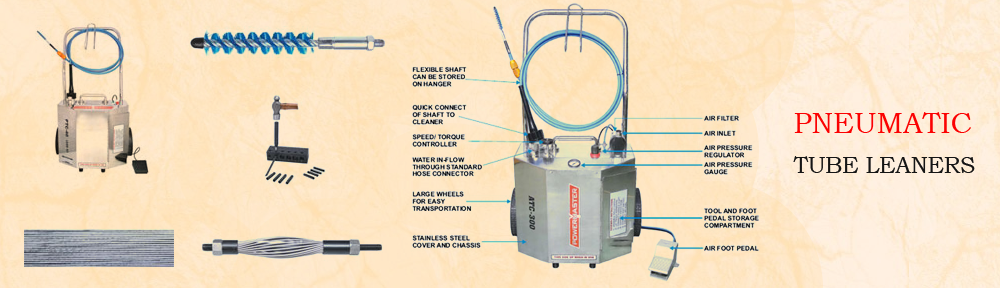

Its features

One has to ensure that the following features are to be present when trying to avail Sugar Factory Tube Cleaners, like:

- The process of tube cleaning is not to be a complicated one. Rather, the entire process needs to be simple, smooth and quick.

- The employed shaft that is used for the purpose of cleaning needs to be flexible. This way, complex designs of tube curves could be cleaned without any difficulty.

- Cleaning tools, flexible shaft and accessories being easily replaced can ensure effective and efficient functioning of the cleaner, while increasing range of applications.

- The materials which are employed for cleaning the tubes are to resist thermal shocks and corrosion. Damage of any type is not to be caused to the tube surface.

- Working parameters such as flexible shaft speed and water velocity needs to be manageable.

The benefits

The following benefits can be derived by applying tube cleaners within the sugar factory industry:

- Firm’s productivity gets increased. The organization can enjoy better and enhanced efficiency.

- Equipment’s maintenance cost can be effectively brought down because of part replacement.

- Cleaners can be easily maintained.

- Boiler lifetime could be increased effortlessly.

Employing cleaning tools

The sludges and scales formed may differ for different organizations, their working conditions, their capacities, and with seasons. Some commonly utilized tools given below:

Soft scales and rust can be removed easily. For dealing with impurities, expanding brushes are employed.

- For manufacturing cleaning tools, stainless tools are used widely.

- All non-ferrous and ferrous tubes can be cleaned effectively and efficiently.

- Depending on the deposit types, one can obtain specially designed cleaning tools.

- Scrubbers are to be used for removing harder deposits.

Getting to know the above can help the person to maintain the tube cleaners to ensure that the sugar factory is up and running smoothly.