Cleaning tubes is considered to be an essential and regular activity that is generally encountered in various fields such as sugarcane industries, oil refineries, power plant equipments, etc. For ensuring smooth functioning of the firms, there is a need to get prepared for dirtying the hands! However, one can make use of advanced technology by seeking the best Portable Electric Tube Cleaners manufacturers, who can provide the most appropriate solutions, to cater to the specific requirements.

Importance of regular cleaning

To get to know tube cleaning importance, there is a need to understand the consequences that emerge from unclean boilers.

- The boiler’s operating conditions are termed to be intense. High pressures and temperatures may be experienced within the boiler which favors formation of sludges and scales.

- In case, these are ignored, they would act similar to that of heat insulators, decreasing material conductivity to dangerous levels.

- Firm’s efficiency drops, since there is noticed necessary fuel input increase.

- Rapid corrosion is noticed and a stage comes, where components may be utilized for nothing!

Therefore, it is no use to delay the cleaning process, however, keen and prompt attention is to be paid to it. One should employ tube cleaners immediately for enhancing productivity.

Its features

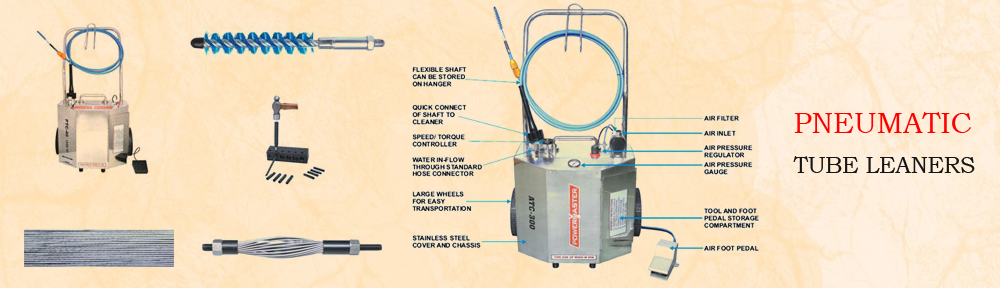

The following features are present in electric tube cleaners.

- They are much lighter and compact, thereby making it much easier to be used in any of the complex working area.

- A provision is present in the shaft that helps water to be flushed out at higher velocity. Sludges and soft scales are forced by the flowing water out of tube.

- The cleaner can be operated with great flexibility by using the foot switch. It can assist the operator to focus upon the cleaning procedure.

- By having mobile trolleys employed, one can ensure easy locomotion within work area.

- Tubes of all complex design can be cleaned comfortably by using the flexible shafts. Also, such flexible shafts could be changed for making it to be used for different applications.

- The shaft’s speed and flowing water’s velocity is adjustable.

Its functioning

Flexible shaft that comes with high speed rotation, is said to be attached with cleaning tool. Actual work to discard sludges and scales in tubes is done by the cleaning tool. Various cleaning tools can be employed, depending upon deposits which are to be eliminated the tube material. At the same time, care is to be maintained for ensuring that the cleaning tool is good enough not to cause damages. Harder deposits can be eliminated by employing carbide drills. The separated debris gets forced out due to water jet’s impact through shaft.

Few precautions to be taken

- It is to be ensured that all hydraulic and electrical connections are tightly secured.

- Operator is to be familiar with instructions provided within the manual.

- Safety devices are to be used when operating such as goggles and gloves.

- Only specified cleaning tools are to be used for the application.

Following the above is sure to help the person to achieve greater productivity at the workplace.