The tube cleaners find use for cleaning choked tubes. You need tube cleaning in different applications in diverse situations. Most common applications are chiller tube, absorption machines, and heat exchangers. Tube cleaning is also needed in evaporators, condensers, and boilers.

Operating technique of the tube cleaner

Usually, the cleaning operations are one-man processes if you have a small size the tube that needs cleaning. The cleaning process is straightforward. Water enters the shaft and the operator directs it into the tube he cleans. The high-pressure water softens the scales and dirt and the rotating brush at the tip of the cleaner helps in removing the scales. Typically, one uses either brushes or drills for the cleaning operation. If the amount of deposit is more and hard, then one uses carbide drills. For light cleaning operations, one uses a nylon brush.

Different types of cleaners

There are many kinds of tube cleaners. They find use depending on the situation and the kind of tube you need cleaned. These are as follows:

- Electric tube cleaners

- Pneumatic tube cleaners

- Portable electric tube cleaners

- Portable pneumatic tube cleaners

One uses smaller models for cleaning condensers, oil coolers, and small heat exchangers.

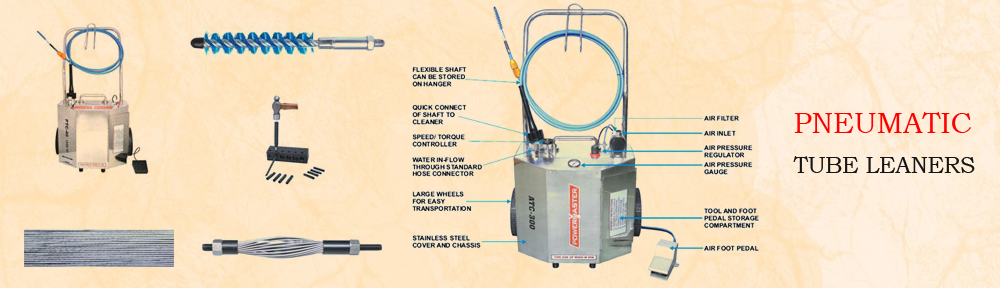

Parts of the tube cleaner

The parts of the portable pneumatic tube cleaner are as follows:

At the front end, we have the driven shaft. You attach this to the shaft coupling, which locks on to the drive shaft. The drive coupling connects this through a threaded connection to the cleaner. You have an opening for the water and a trigger to start the flow. By changing the flow of water, the cleaner can enhance or decrease the quality of the cleaning process. The body is corrosion resistant stainless steel. This gives the cleaner a long life, operating in the harshest environment efficiently.

Necessity for cleaning

Cleaning is a necessary process since choked tubes will decrease the rate of heat exchange. This brings down the efficiency of the machine. By cleaning at least once in a year, you keep the tubes free and help the machines keep up operations with good efficiency levels.

Advantages of the cleaner

The outstanding feature of these cleaners is the extreme portability. One may take the portable pneumatic tube cleaners anywhere since they are light. You can connect them to any power source, pneumatic or electric and begin to use them straight away. They need less maintenance and have a long life. Their parts are durable. You can change the different accessories such as the shaft and use one with a different diameter. Or you may attach a different brush to the tool tip for use in a different situation.

You can use these cleaners on the fireside of boilers of any type of fuel. One can use them in many ways for cleaning the water side of the tubes in the boiler. You can use the rotary method of cleaning in the normal course. For special situations, you might need to use chemical cleaners for more effective cleaning or when the tube diameters are too small. In this way, you can clean both the water tube boilers and the firetube boilers.