Introduction:

For those operating in industries that need the employment of a system of tubes, like those in heat exchangers or condensers, smart tube improvement instrumentation could be a should. Once you swear a good deal on such a system, it’s positively in your interest to stay the system in ace form.

In each tube system, as time passes and as, for instance, water and air pass through the tubes, materials will and do accumulate, like sludge, alluviation, or corrosion deposits. If not removed or otherwise proscribed, these materials will create the operation of that tube system problematic. Therefore, the tube system has to be clean from time to time to stay it operating properly.

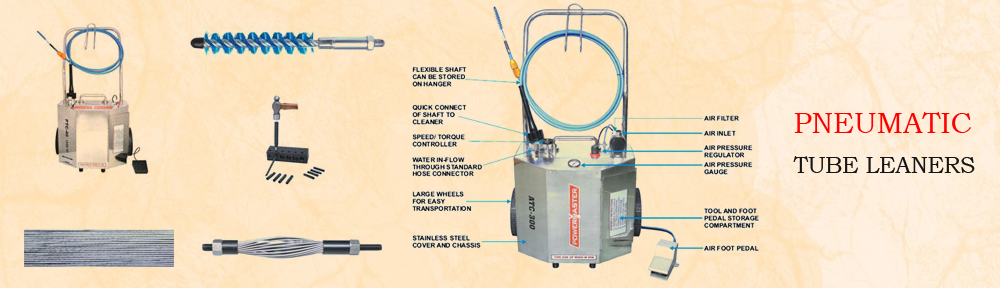

There are after all a lot of ways that then one to wash tubes, and not all of them create use of tube improvement instrumentation. Those seeking to wash tubes even have the choice of resorting to strictly chemical suggests that, like acids or varied improvement solutions, as an example. However, not all styles of tubes or systems product of tubes are often clean using such suggests that – those systems that incorporate some plastic in them, as an example, are often terribly sensitive to chemicals. For such tubes or tube systems, the mechanical suggests an improvement, that brings in the use of Electric Tube Cleaners could also be best.

Electric Tube Cleaners are tools that scrape the inner sides of tubes, balls whose surfaces are abrasive, or cylinders with bristles all around them are often slipped into tubes at the side of some water or an improvement answer. Because the cleaner moves at the side of the answer or water, it scrapes away the deposits that are flushed out at the so much finish of the tube system. One could elect to create use of a pressure jet, or an outsized quantity of water moving at a speedy speed, to extend this method’s rate of success.

Electric Tube Cleaners work on identical vacuum suction principal however additional safeguards should be placed in situ so water doesn’t are available contact with any electrical parts or the vacuum motor. Wet-dry vacuum motors are typically positioned on prime of a rubble canister and the air is drawn in through the hose and up through the vacuum motor to an exhaust vent positioned on prime. If water starts to achieve the motor at the highest of the canister a floating ball can shut off the gap into the motor saving the motor from water harm. All on and off switches and electrical parts on wet dry vacuums are sealed to stop water penetration.

Conclusion:

Portable Electric Tube Cleaners suppliers use high steam-powered motors to form a vortex within the vacuum that creates suction. A beater bar pushes rubble into the suction tube that is then required into a sealed canister. Once within the canister, the rubble is affected toward the outer walls using centrifugal forces. The rubble then slows down and is born into the rock bottom of the canister by utilizing gravity. Most of the Portable Electric Tube Cleaners suppliers do not use filter luggage however generally this will compromise air quality owing to escaping mud particles.