Today, a majority of the manufacturers from various sectors make use of heat exchangers. If your firm has it, the major problem you would encounter is its fouling. It has a significant impact on the productivity of the firm. Here under, we provide you a few aspects to be considered in the cleaning process of shell and tube heat exchangers.

When to clean:

Cleaning the heat exchanger at the right time is essential to ensure its prolonged lifetime. In industries like pharmaceutical, dairy, food and other sanitary industries, there are established protocols to clean for the timing of cleaning. If the firm is equipped with an automated clean in place system, you don’t have to disassemble the exchanger parts. An interval time is established by a firm to schedule its heat exchanger cleaning activities. This is dependent on various factors like the metallurgy of the product, working fluid and other parameters. Few materials tend to get fouled easily and the cleaning has to be done more often to clean such equipment. Of late, these devices are so designed and manufactured that it requires least attention towards cleaning. It can run effectively for years without cleaning. If the production levels drops down significantly, it’s a sign indicating to clean the equipment.

Getting prepared:

Before setting out to clean the device, you have to make a checklist of the things to do on the day of cleaning. This helps you to keep track of the important tasks. It should include the following:

- The operating parameters of the machine just before it shuts down.

- The physical specifications of the machine to be cleaned.

- Possible negative effects of the cleaning process on the heat exchanger.

- Get to know parts which are likely to be replaced and have such spare parts in the kit.

- A detailed and safe plan of lifting and disassembling.

Cleaning tips:

- Record and document every step of cleaning process. It is essential to have photographs of the heat exchanger at every stage. Apart from helping us to explain the damages caused, it also serves as a reference to someone novice.

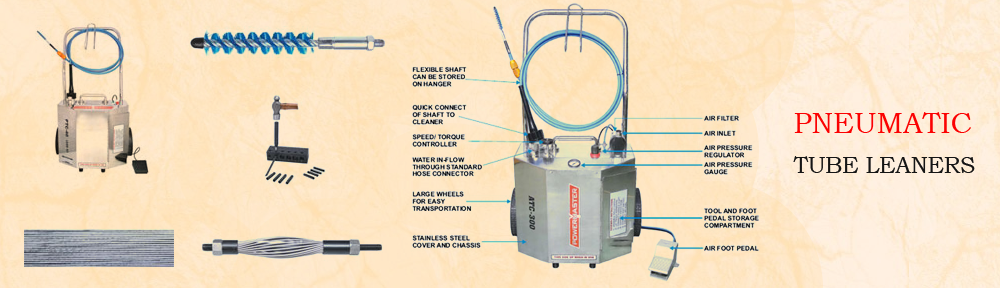

- Mechanical cleaning: This is the most widely preferred cleaning method for heat exchangers. Look out for the best tube cleaning accessories manufactures to purchase all essential tools. The first step of this process is to determine the type and thickness of the deposits to be removed. Accordingly choose the cleaning tools or brushes for the intended purpose.

- Hydro blasting: The risk of injuries in this method is relatively high. Extreme precautions have to be taken to avert any possible accidents. In this process, the water is subjected to intense pressure and then it is forced onto the deposits.

- Chemical cleaning: Despite being an effective method, it hasn’t gained a wide popularity. Mildly acidic substances are made to react with the deposits to remove them. In this process, you have to carry out a secondary cleaning process to remove the chemicals.

Consider all the pros and cons of the each cleaning process and select the one, which best fits your equipment.